Finishing wood with natural oil can be a great way to both protect and beautify the wood project you’ve been working on. Pure tung oil is a popular choice for treating and finishing as it penetrates deep into the grain of bare wood surfaces. Danish oil vs tung oil?

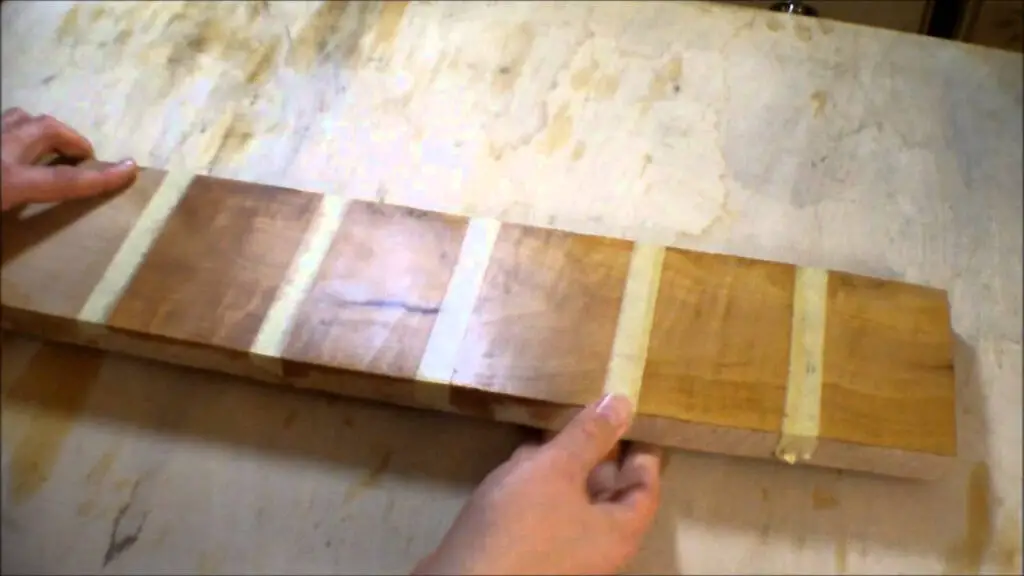

To apply pure tung oil, mix some varnish and mineral spirits together in parts that are equal to the pure tung oil portion then apply it to the wood surface with a clean cloth. Make sure to rub it in well and let the surface dry before applying any follow-up coats. With pure tung oil applied correctly, you’ll have beautiful, natural protection for your wood project!

When it comes to oil finishing for projects, tung oil and Danish oil are two of the most popular types being utilized. Tung oil is derived from seeds of tung trees and when applied, penetrates deeply into the wood while forming a hard but elastic coating that brings out the natural beauty of wood.

Excess can be wiped away with a cloth or let to cure naturally. On the other hand, Danish oil is not actually an oil at all, but just a thinned varnish. It provides Limited protection against moisture and won’t penetrate as deeply into the wood as tung oil does. Regardless both provide an attractive finish; however you must apply each correctly to be sure they are appropriate for your project needs.

- What Is Danish Oil?

- What is Tung Oil?

- Danish Oil vs. Tung Oil

- Waterproofing

- Application Time

- Durability

- Appearance

- Food Safety

- Checking Quality of Tung Oil

- Is Danish oil better than tung oil?

- What are the disadvantages of tung oil?

- What are the advantages of using Danish oil?

- Does Danish oil make wood waterproof?

What Is Danish Oil?

From wooden furniture to musical instruments, Watco danish oil dries is a well-loved choice for bringing out the beauty of wood. Crafted from an exquisite blend of varnish and oil, this finish can add luster and vibrancy to any piece.

Woodworking experts from Denmark discovered a unique oil blend that revolutionized their craft. As boiling linseed oil was too difficult to apply, they experimented one oil by combining it with varnish and thinner in equal parts – creating the revolutionary apply danish oil!

Woodworkers quickly discovered that recommend danish oil was the perfect solution to their needs; it not only provided a simple application and speedy drying time, but also had the potential for mass production. As this product gained in popularity among craftsmen everywhere, manufacturers soon produced different versions of Swedish oil until it became widely available – an essential item for all woodworking projects!

What is Tung Oil?

Unlike Danish oil, tung oil is 100% natural. This unique product originates from the nut of a tung tree – but don’t worry about having to crack open any nuts! The process involves pressing and refining the nut for its potent oils that give wood surfaces an unbeatable finish.

To achieve optimal penetration of wooden surfaces, tung oil is commonly blended with an additive such as mineral spirits or thinner. This custom mixture and ratio are determined by the manufacturer to create a perfect finish for whatever purpose it will serve.

Tung oil was first discovered and put to use thousands of years ago in the Orient, but its popularity rose when shipbuilders in China started using tung oil to treat the exterior surfaces of their ships. The main reason for this was due to tung oil’s outstanding water-resistant quality, however it has other advantageous qualities too.

Applying boiled linseed oil after tung oil will give a harder finish that takes more time to wear away, helping ships retain their structure and strength even longer. However too much tung oil should be avoided, as chances are excess amounts mineral oil would need to be wiped off by a cloth, making it damaging for the environment if not taken into consideration early on. A tung oil finish is relativelyeasy to apply and maintain with regular topping up every two or three years; therefore making it an ideal choice for treating boats of all kinds.

Danish Oil vs. Tung Oil

Waterproofing

If you are looking for waterproofing qualities in a product, Danish and tung oils come out ahead of teak oil. That’s not to say that Danish oil isn’t also an outstanding option; it is a durable product which is great for water resistance too. It falls a bit short of tung oil, however, which stands alone when it comes to water-resistance and nearly reaches the waterproof mark. As such, if your project involves working with wood which needs to be sealed against moisture, there can only be one choice – tung or vs danish oil.

Application Time

Danish oil is a special type of oil that is ideal for completing projects quickly. It dries much faster than tung oil due to different chemicals in its formula, making it perfect for anyone who needs the job done fast! Furthermore, the type of wood used with Danish oil matters less in terms of drying time than when using tung oil; this means you can work on your project without worrying about extra delays due to incompatibility of the wood and wood finishing oil. Danishing oil is also incredibly easy to apply, making it an excellent choice for DIY projects or for those new to finishing wants that need results fast.

Before you can truly appreciate the beauty of your wood project, it’s time to break out the tung oil! Applying several coats completely natural product is a multi-step process that takes some patience – with each coat taking up to 48 hours or more for full curing. The good news? Your hard work will be worth it in no time and you’ll have an exquisite final product ready for all kinds of admiring eyes!

Applying tung oil to your project can add a unique luster and protection. But, don’t underestimate the amount of time it will take! Sanding the entire surface between each coat is an essential part of this labor-intensive process that should not be overlooked – especially if you’re dealing with something large like a boat. Make sure to factor in plenty of curing and sanding time when setting up your timetable for completing this special job.

Danish oil is the speed demon of wood finishing oils, with each coat drying in as little time as a half hour – depending on the project and product. But don’t get ahead of yourself; always follow manufacturer directions to guarantee your masterpiece receives just the right amount of shine!

For the perfect finish, sanding between coats may be necessary – but sometimes a simple wipe-down of your project is enough for smooth application. Danish oil penetrates deeply and works wonders on hardwoods like cherry, oak, ironwood and maple!

Durability

Danish oil may not live up to the long-term durability of other oil treatments or tung oil, which is quite intensive and laborious in its application. However, with a significant effort comes great rewards; making this investment can undoubtedly prove beneficial down the line.

With the power of tung oil, you can create a lasting bond between your wood and an ultra-durable finish that is capable of defending against various forms of damage! This protective layer – formed once the wood is saturated in this distinctive oil – creates a hard, yet natural result as it helps protect from water spots, scratches and any other undesirable incidents.

For an end result that’s sure to stand the test of time, investing in tung oil for your next project is a no-brainer. It can take more effort during coating and drying than Danish oil, but you’ll be rewarded with greater resilience against impact and weathering – well worth it!

Appearance

When trying to decide which oil finish will work best for your project, consider tung oil if you want a reliable result that won’t drastically change its color over time. Linseed and Danish oils may be faster-curing options but their respective shades can alter significantly with age.

If you’re hoping to achieve a natural finish with an attractive wood finish, you have two great options – tung oil and Danish oil. Tung will bring out the natural hue and texture of your chosen material, perfect for a rustic effect; while Danish is blended with varnish to give that extra professional touch by emphasizing grain and color. Either way, it’s guaranteed to look beautiful!

Food Safety

If you are planning a project that will involve food, finding the right oil is essential. Fortunately, tung oil in its natural state provides suitable protection for items near or holding edibles; although it’s important to note diluting this substance with any additives may decrease its safety unless they meet certain standards. Danish Oil pales in comparison as an edible-grade option!

Wooden bowls crafted for food should be treated with care. Tung oil is the best choice true oil to saturate and finish these vessels, as opposed to Danish oil which has varnish components not suitable for consumption.

Checking Quality of Tung Oil

Before investing in a product that claims to use tung oil, it’s important to check what really makes up the finish. Read reviews from people who have tried out different products – if there isn’t enough natural tung oil listed on the label or ingredients, then you could end up with an inferior finish!

Buying pure tung oil is the best way to apply tung oil finishes to your project. It can be more expensive than a pre-made solution, but you won’t have excess amounts of other oils in it like danish oils might have. This can help you apply a high-quality finish and avoid any distraction from the beauty of the wood grain under the oil.

When you apply tung oil to wood, apply small test patches on scrap wood before full application. This will let you evaluate if the solution is too thick and needs thinning, or if there are issues like poor absorbance or excess oil or residue that need addressing. With this method, creating a beautiful tung oil finish is simple and straightforward; continuing with care and patience should result in an exceptional wood finish.

Ultimately, natural wood finishes, like Danish oil and tung oil are very similar. They are beloved wood finishing oils and often used for oil treatments.

However, if real tung oil is not an option, many recommend opting for Danish oil instead – although it does dry somewhat faster than its counterpart, it might not be quite as durable or as water-resistant. That said, both can result in a beautiful natural look to any wooden surface if applied correctly.

Is Danish oil better than tung oil?

Tung oil is a perfect wood oil suited for a matt finish. Generally, for most surfaces we recommend Danish oils because dries quickly and gives a tougher finish to wooden furniture.

What are the disadvantages of tung oil?

Besides being expensive, it can cause water-ring scratches or stains. The cost usually exceeds that of the linseed oils.

What are the advantages of using Danish oil?

Danish oil is an extremely versatile and water resistant oil. So if you want genuine wooden cooking tools, kitchenware, tools or handles this can be the most popular product you can get them from. This dries to a hard satin finish and requires very little maintenance.

Does Danish oil make wood waterproof?

Danish oils were originally used to make sand and gravel on ships due to their antiseptic properties. It can be used for wood that needs protection from the elements. There is no waterproof finish in this product. If you need to have waterproof finish marine varnish may be an excellent alternative.

Read more: Whats is birch soft or hardwood?

![Sapele vs. walnut wood [5 main differences] Sapele Vs. Walnut Wood: Top 5 Differences & Best Guide](https://bestwoodforcarving.com/wp-content/uploads/2024/01/wood-53-335x220.jpg)

![Mango wood furniture pros and cons [9 tips] Mango wood furniture pros and cons + 9 tips before you buy](https://bestwoodforcarving.com/wp-content/uploads/2024/01/wood-51-335x220.jpg)

![Which advantages and disadvantages of hickory wood? [8 factors] Top 8 Disadvantages Of Hickory Wood: Best Helpful Guide](https://bestwoodforcarving.com/wp-content/uploads/2024/01/wood-38-335x220.jpg)

![How Long Do Wood Pellets Last? [6 Essential Insights Unveiled] How long do wood pellets last](https://bestwoodforcarving.com/wp-content/uploads/2023/12/How-Long-Do-Wood-Pellets-Last-6-Essential-Insights-Unveiled-2-335x220.jpg)

![Tung oil vs polyurethane [4 main comparison factors] Tung Oil Vs Polyurethane: Top 4 Factors & Best Helpful Guide](https://bestwoodforcarving.com/wp-content/uploads/2023/12/wood-14-335x220.jpg)

![Is tung oil flammable? [7 Preventive measures] Is Tung Oil Flammable: Top 7 Safe Tips & Best Guide](https://bestwoodforcarving.com/wp-content/uploads/2023/12/What-is-a-Wood-Planer-3-335x220.jpg)