Wood warping can be disastrous! Whether you’re a woodworker or a homeowner, it’s important to take preventive measures against wood warp. It is caused when the equilibrium moisture content of wood changes, which alters the wood fibers along the length, width, or thickness dimension to produce common forms of warped wood – cupping, twisting, bowing, and crooking. How to prevent wood from warping?

One preventative step for homeowners is to regularly inspect their home for any signs of warp and adjust air-conditioning and heating appropriately. For those working with wood in professional settings like carpentry workshops, preventing wood warps, can be accomplished by Kiln drying and regulating humidity levels in the work environment. With these simple steps implementing them in your daily routine can help you ward off warped wood and successfully maintain equilibrium moisture content.

Woodworking projects always look best with wood that is of a stable variety and the proper techniques can help you achieve that. Proper storage techniques at the right temperature and humidity levels are key to preventing wood from warping, as well as ensuring proper ventilaton – wood should be able to absorb moisture evenly.

You should also make sure that wood is properly dried out, avoiding excessive heat or quick drying processes which can only increase the chances of wood becoming warped. If woodworkers follow these steps when crafting pieces from wood, they will have a much better chance at producing a quality woodworking project.

Wood warping can be a major concern for those involved in the carpentry industry. Warped timber is not only difficult to fix, but also it renders the wood useless for its intended purpose and decreases its overall value.

How to prevent wood from warping?

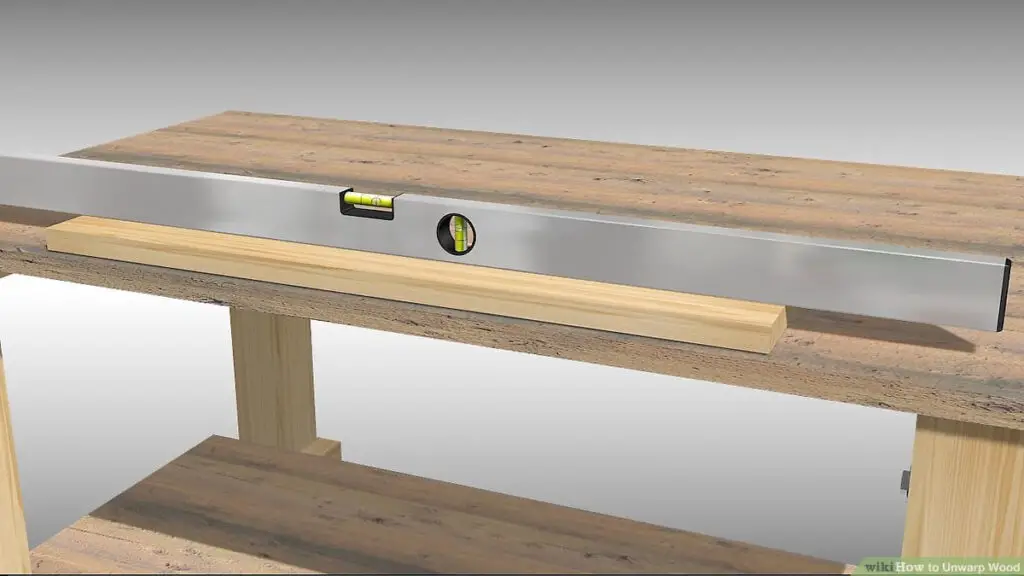

To prevent wood from warping and fix warped wood, carpenters must take a few simple actions such as kiln drying to absorb moisture, laying down timbers flat, and controlling relative humidity levels. Trying to fix warped wood without stabilizing it first can cause bigger issues in the future and make the process even more of a headache.

Overall, taking preventative measures to prevent warped wood will save money and keep valuable pieces in circulation longer, making it easier for those involved in construction or carpentry to ensure their work meets standards.

Wood warping can be a cause for concern for carpenters and those involved in the construction industry, as it compromises the integrity of the timber and renders it unusable. Thankfully, there are steps that can be taken to prevent wood warping and preserve its quality long-term. Storing wood properly is key; kiln drying to absorb excess moisture and laying down timbers flat help keep wood stable.

Additionally, proper ventilation helps control relative humidity levels which also helps prevent wood from becoming warped. Skipping out on these preventative measures could worsen the condition of warped wood or even render it useless. Taking these actions will not only save money but also keep valuable pieces in circulation longer and make it easier to ensure work meets standards.

UNDERSTANDING THE CAUSES OF WARPING

Warping in wood is a relatively common and concerning issue that can halt any project. Incorrect layering of flat boards is only one edge of the main causes for warping and should be avoided. Additionally, it’s essential to remember that wood needs to be relatively dry with a relatively high moisture content prior to staining. Absorbing added moisture that is released by the stain can cause dramatic changes which lead to uneven shrinking and expansion, resulting in warping.

Acclimating the wood prior to starting any project or whenever necessary ensures that the wood does not contain any added moisture from surrounding environments which can help alleviate warping issues when staining wood. Overall, understanding these primary factors before working with wood will save you time, energy and money in the long run!

Moisture Level And Changes In Humidity

Wood is an important material that has many applications in various home projects. Because wood is hygroscopic, it absorbs and releases moisture in relation to its environment. However, when too much moisture is taken up by the wood, it can expand in size and become warped.

To avoid this, lay wood flat instead of upright since all four surfaces absorb moisture differently. In addition, applying a wood stain can help slow the absorption of moisture; this will help preserve the shape and stability of the wood once finished with a project. By using less moisture and following these steps, wood warping can be avoided and projects can be completed without repair or deterioration from improper humidity moderation.

Warping is a distressing phenomenon caused by too direct sunlight and much time spent in dry air, resulting in the unwelcome transformation of wood from its original state to an unsightly shape.

Improper Drying Or Storage Of Wood

Warping is a common challenge for many woodworkers, but often it can be avoided by ensuring the timber has been correctly dried and stored. Excessive moisture in the drying process or variability of humidity during storage can cause misalignment as materials react to these changes. As such, proper attention must be given at each stage from selection to completion if perfect results are desired.

The Thickness Of The Wood

Wood is uniquely sensitive to its environment, often responding dramatically to changes in moisture or temperature levels – bending and twisting according as if it were an organic part of nature’s forces. Thinner sections are even more prone to warping than thicker ones; the flexibility these delicate pieces possess make them especially vulnerable when exposed to elements outside their control.

Different thicknesses of wood can produce drastically different results. While thin pieces may easily warp and contort once exposed to certain conditions, thick slabs are much more resilient – able to keep their form even after drying out.

Not only do different pieces of wood vary in appearance, they differ in strength and load-bearing capacity too! Thicker boards are typically more resilient than their thinner counterparts – better equipped to withstand heavy weights without succumbing to pressure.

Wood Grain Orientation

Wood boards used for furniture, flooring and other purposes can be adversely affected by changes in humidity or exposure to moisture. Warping is the result of these factors altering the grain structure within each board, compromising its structural integrity.

With the grain running along its width, a board of wood can be remarkably strong and rigid – perfect for applications where stability is key. This orientation offers protection against bending or curling as well as warping brought on by moisture over time.

Pressure-treated wood, with its added chemical protection against moisture, is transformed and strengthened through a particular grain alignment along its width – working to keep the shape intact.

Incorrect Installation Or Use Of Wood

To ensure wood stays true to its form, nailing and screwing should be done with precision. Picking the correct length and size of nails or screws will help avoid deep penetration into the fibers leading to misshapen results.

Protect your wooden possessions from the elements with a protective coating and keep them away from heat sources! Moisture is one of the biggest culprits behind warped wood, so be sure to seal outdoor pieces properly – that way they can last for years.

Warping wood is an issue that many wood crafters, woodworkers, and furniture owners have to deal with over time. Fortunately, there are precautionary measures that can be taken to prevent wood warping and keep wood objects looking good. One of the easiest ways to store wood furniture or woodworking projects is in a climate-controlled setting where it does not come into contact with moist air.

This prevents moisture absorption in wood, which is one of the main reasons for wood warping. Additionally, allowing wood items to release moisture before and after use also helps prevent warping down the line. Taking these precautionary measures will ensure that wooden objects retain their original shape while protecting them from long-term warping.

TYPES OF WOOD WARPING

To avoid wood warping, it is vital to understand the various kinds of wooden warping and their causes. One of the most common types is related to moisture absorption; when exposed to high humidity or excess amounts of water, the cells found in wood expand significantly, leading to warping.

Wood warping can also be caused by an inadequate acclimation process—when wood adjusts to its new environment. To avoid these issues, it is critical for wood to be dry before beginning a project and to acclimate wood slowly and thoroughly when necessary. Being aware of these causes of wood warping will help craftsmen avoid potentially considerable damage and wasted time down the road.

Bowed wood

Wood bowing is an insidious enemy to the craft of carpentry and construction, as it causes wood boards to cleverly contort against their natural shape. This unusual warping can be brought on by a range of conditions such as uneven drying or humidity levels, improper use in building materials or even devious installation techniques – all which leave wooden beams susceptible to failure.

Twisted wood

Warping caused by uneven drying and inadequate mounting can turn boards into a twisted, unusable mess. Not only aesthetically unpleasant to look at, such wood is unsuitable for carpentry projects due to its weakened strength – an undesirable outcome of careless storage methods.

Kink

Having a “kink” in the wood can be more than just an eyesore; it affects much of its integrity, strength and ultimately reduces any potential that timber may have for construction or carpentry projects. This twisted angle is usually caused by improper storage conditions, uneven drying methods or incorrect assembly techniques.

Crooked wood

Warped wood, with its unique twist and contortion, can make it difficult to properly utilize in carpentry or construction projects. Often caused by uneven drying or inadequate storing of the board, this type of bending creates an unstable surface between top and bottom – making sure no two pieces are exactly alike!

Cup

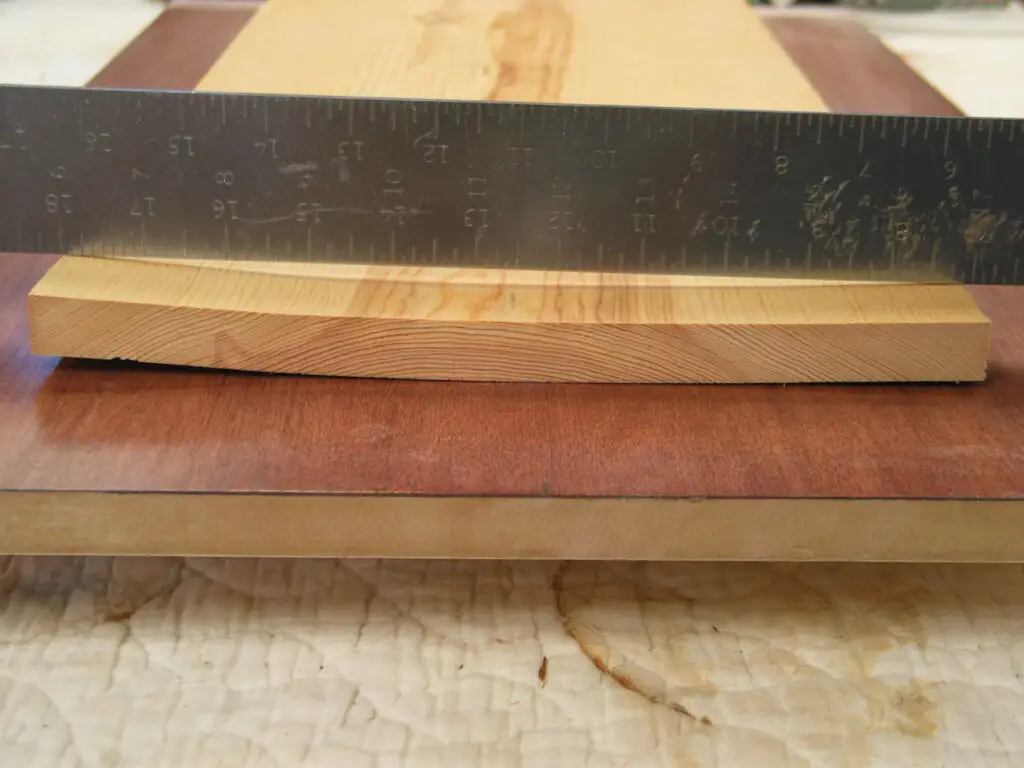

The effects of moisture content and uneven drying can wreak havoc on wood, creating an issue known as “cup”. This unfortunate phenomenon causes the edges of a board to become elevated in comparison to its center, compromising the material’s structural integrity when used for carpentry or construction projects. Without proper handling during installation and use, this effect could prove disastrous.

CONCLUSION

Warping of wood, caused by everything from too much humidity to careless handling and application, can have far-reaching consequences beyond just weakening its structural reliability. Not only could it put a strain on crafting or building projects in terms of strength – but also bring down the overall visual appeal as well.

Properly preserving wood is essential to avoid warping and other damaging effects, so take certain steps to protect your lumber. Carefully select the species of wood most suitable for the task; apply a protective finish like varnish or sealer; make sure it stays flat when stored away in an environment conducive to its preservation – nothing too hot nor cold with good air circulation – store securely before use, test moisture content levels beforehand, keep from rapidly drying out any pieces you might be using as well as over-drying them if not immediately used. Follow these guidelines for lasting success!

Woodworkers and builders can ensure their projects are held to the highest standards by taking preventative steps against warping. Doing so gives each piece an exquisite finish that stands out, while also ensuring joints fit together with ease – making it more attractive for both themselves and anyone looking to buy.

Warping in wooden creations can be a bummer, but it doesn’t have to ruin your next project. By following these simple tips you will not only guarantee long-lasting durability of your wood projects – their artistic allure will also remain for years to come! It’s easy and could greatly enhance the final result so don’t miss out on essential steps like this one.

Read more: How long does untreated wood last outside?

![What is a Wood Planer? [4 Types of Wood Planers] What Is A Wood Planer: Best Helpful Guide & Top Review](https://bestwoodforcarving.com/wp-content/uploads/2023/12/What-is-a-Wood-Planer-335x220.jpg)