What is a wood planer? Woodworking planer, an age-old craft, relies on many tools to transform raw timber into finely crafted pieces of art or functional structures.

One such indispensable tool in a woodworker’s arsenal is a thickness planer. This device plays a pivotal role in achieving precision and smoothness in the surface of the wood, enhancing the overall quality of the finished product.

![What is a Wood Planer? [4 Types of Wood Planers] what is a wood planer](https://bestwoodforcarving.com/wp-content/uploads/2023/12/bestwoodforcarving-1.jpg)

- How a wood planing machine works

- Types of Wood Planers

- Hand Planer

- Surface Planers

- Benchtop Planers

- Stationary Planers

- The Wood Planning Process

- Uses of Wood Planers

- Surface Smoothing

- Thickness Control

- Resurfacing and Recycling

- Maintaining a Wood Planer

- Blade Sharpness

- Cleaning and Lubrication

- Safety Precautions

- Conclusion

- Frequently Asked Questions

- What do you use a wood planer for?

- Is a planer better than a sander?

- What is the point of a planer?

- What is a wood hand planer used for?

- What is a woodworking plane?

How a wood planing machine works

A wood planer, also known as a thickness planer, is a woodworking tool designed to trim boards by shaving off layers of material and ultimately, creating smooth square edges for building furniture or the next woodworking project.

It consists of a flat base with a rotating cutter head, usually equipped with rotating blades or knives.

The exact thickness of the wood can be controlled by adjusting the planer’s cutting depth, allowing craftsmen to achieve the desired thickness with precision.

Types of Wood Planers

Introducing the various types of wood planers opens a gateway to understanding the specialized tools that cater to distinct woodworking needs.

Each type brings unique features and advantages to the woodworking craft, from handheld planers for precision to stationary and benchtop planers for efficiency.

Hand Planer

Hand planers represent a fundamental aspect of woodworking craftsmanship. In the traditional approach, woodworkers skillfully employed hand planers, guiding the tool manually over the wood surface.

This hands-on technique demanded a high level of skill, precision, and control from craftsmen who sought to shape and refine their projects with meticulous detail. However, with the advent of modern technology and woodworking practices, the industry has witnessed a significant shift towards electric planers.

These contemporary tools, powered by electricity, bring efficiency and speed to the wood planing process.

While the manual artistry of hand planers remains cherished, electrical planers have become increasingly popular for their ability to handle tasks swiftly and with less physical exertion, making them a practical choice for woodworkers seeking a balance between traditional craftsmanship and modern efficiency.

Surface Planers

Surface planers, also known as power jointer, play a pivotal role in the initial stages of woodworking by addressing one of the foundational aspects—achieving flat and straight surfaces on lumber.

The jointer planer is designed to level the faces of boards, ensuring they are free from twists, warps, or irregularities.

Woodworkers utilize this tool to create a uniform and stable foundation for subsequent phases of the project, such as joinery or further dimensioning.

The key function of surface planers lies in their ability to flatten one face of a board, providing woodworkers with a reference point from which to achieve parallel thickness.

Whether preparing rough stock for cabinetry, furniture, or another woodworking project, the surface planer stands as an indispensable tool for establishing a solid starting point and laying the groundwork for precision and quality in the final piece.

Benchtop Planers

Benchtop planers represent a valuable category in the realm of woodworking tools, striking an optimal balance between compactness and versatility. These benchtop planers are ideal for hobbyists and those operating in small-scale woodshops.

Benchtop planer offers a user-friendly solution for achieving uniform and smooth surfaces.

A benchtop wood planer is a robust machine that can efficiently process moderately sized pieces of wood. The compact nature of the benchtop planer makes it easy to store and maneuver, appealing to woodworkers with limited workshop space.

Additionally, benchtop planer is often more affordable than larger, stationary counterparts. Benchtop wood planer is an attractive choice for those starting their woodworking journey that doesn’t require massive processing capacities.

Whether smoothing rough-cut lumber or ensuring consistent thickness, a benchtop planer proves to be an indispensable tool for those seeking functionality without compromising on space or budget considerations.

Stationary Planers

Stationary planers emerge as the power solution for woodworking endeavors of a grander scale. Tailored for larger projects, these robust machines stand as formidable floor-mounted entities, providing an unparalleled combination of stability and power.

The inherent design of stationary planers ensures a steadfast foundation, minimizing vibrations during operation and contributing to the precision required for substantial woodworking tasks.

Equipped with potent motors and wide cutting capacities, stationary planers excel in efficiently processing significant quantities of wood, making them indispensable in industrial settings and large workshops.

Whether tasked with smoothing oversized panels or achieving uniform thickness across extensive batches of lumber, stationary planers are the go-to choice for those seeking high-capacity performance and reliability in the face of demanding woodworking challenges.

Their ability to handle large volumes of material makes them an essential asset for professionals engaged in crafting substantial furniture pieces, architectural components, or other expansive woodworking projects.

![What is a Wood Planer? [4 Types of Wood Planers] bestwoodforcarving 2](https://bestwoodforcarving.com/wp-content/uploads/2023/12/bestwoodforcarving-2.jpg)

The Wood Planning Process

The operation of a thickness planer involves feeding rough-cut lumber through the machine. The cutter head shaves off layers as the wood moves along the planer’s base, leaving a uniform and smooth surface.

Once the wood has been meticulously planned to the needed thickness, the next step often involves the crucial process of glue-ups.

Woodworkers carefully join multiple planned pieces, ensuring a strong and seamless bond. This step is particularly vital when crafting larger structures or intricate designs, where precision in thickness and surface smoothness contributes to the success of the glue-ups.

This process not only enhances the aesthetics of the wood but also ensures uniform thickness, a crucial factor in a woodworking project.

Uses of Wood Planers

Wood planers serve various purposes in woodworking, making them an indispensable tool for professionals and hobbyists.

Surface Smoothing

The primary function of a thickness planer is to create smooth, flat surfaces on rough-cut lumber using the rotating blades of the cutter head. This is particularly important when joining multiple pieces of wood or preparing surfaces for further detailing.

Thickness Control

Woodworkers often require wood of a specific consistent thickness for their projects. A thickness planer allows precise control over thickness, ensuring uniformity across the entire piece.

Resurfacing and Recycling

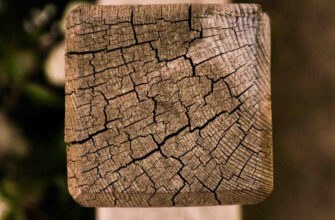

Planers are also used for resurfacing damaged or old wood. By removing a thin layer, craftsmen can reveal fresh, unblemished wood beneath surface imperfections.

Additionally, planers are instrumental in recycling wood by salvaging reusable material from discarded pieces.

Maintaining a Wood Planer

Proper maintenance is crucial to ensure the longevity and efficiency of a thickness planer.

Blade Sharpness

Regularly check and sharpen the cutting blades or knives of the planer. Dull blades not only compromise the quality of the finish but also strain the motor, affecting overall performance.

Cleaning and Lubrication

Dust and debris can accumulate in the planer, leading to problems such as the planer snipe and affecting its precision and efficiency. Regularly clean the machine and ensure all moving parts are well-lubricated to prevent friction and wear.

Safety Precautions

When operating a wood planer, prioritizing safety is paramount to ensure a secure and productive woodworking environment.

Always begin by familiarizing yourself with the manufacturer’s safety guidelines and recommendations.

Utilize appropriate personal protective equipment, including safety goggles to shield your eyes from wood debris and ear protection to reduce the impact of machine noise. Be vigilant about the placement of your hands, ensuring they are a safe distance from the rotating blades and the cutter head.

Additionally, never bypass safety features such as blade guards and anti-kickback mechanisms. Before starting the planer, inspect the machine for any loose or damaged parts, and ensure the work area is well-lit and free from obstructions.

![What is a Wood Planer? [4 Types of Wood Planers] bestwoodforcarving 3](https://bestwoodforcarving.com/wp-content/uploads/2023/12/bestwoodforcarving-3.jpg)

Conclusion

In woodworking, a wood planer stands as a testament to craftsmanship and precision. Whether in the hands of a seasoned professional or an aspiring hobbyist, this tool is pivotal in transforming raw timber into finely crafted works of art.

Understanding its types, uses, and maintenance is key to unlocking its full potential in the hands of those who seek to create beauty from the grain of wood.

Frequently Asked Questions

What do you use a wood planer for?

A wood planer is a woodworking tool essential for refining and shaping wood. Its primary uses include smoothing surfaces to create polished finishes, controlling wood thickness for precision, jointing edges for strong connections, and resurfacing and recycling by removing imperfections.

Is a planer better than a sander?

A planer and a sander serve different purposes in woodworking. A planer is used for thickness and smoothing surfaces, ideal for initial shaping, while a sander is employed for fine finishing and removing scratches. They complement each other, and the choice depends on the specific woodworking task.

What is the point of a planer?

The primary purpose of a planer in woodworking is to achieve precise thickness and a smooth, flat surface on rough lumber.

By removing thin layers of material, the planer enhances the quality of the wood, making it essential for creating polished finishes, ensuring uniform thickness, and jointing edges for strong connections.

What is a wood hand planer used for?

It is beneficial for tasks such as leveling uneven boards, chamfering edges, and refining the thickness of wood. Woodworkers use hand planers for precision work, allowing them to control the amount of material removed and achieve the desired finish on smaller or more intricate projects.

What is a woodworking plane?

A woodworking plane is a hand tool designed for shaping and smoothing wood surfaces. It typically consists of a flat sole, a cutting blade or iron, and an adjustable depth control.

Woodworking planes are used for tasks such as flattening, smoothing, and shaping wood by shaving off layers to achieve precision and a polished finish. They come in various types, each serving specific purposes in woodworking.

![What is a Wood Planer? [4 Types of Wood Planers] What Is A Wood Planer: Best Helpful Guide & Top Review](https://bestwoodforcarving.com/wp-content/uploads/2023/12/What-is-a-Wood-Planer-870x400.jpg)

![How to Use a Countersink Bit? [A 10-Step Guide] How To Use A Countersink Bit: Top 10 Steps & Best Guide](https://bestwoodforcarving.com/wp-content/uploads/2024/07/wood-55-335x220.jpg)